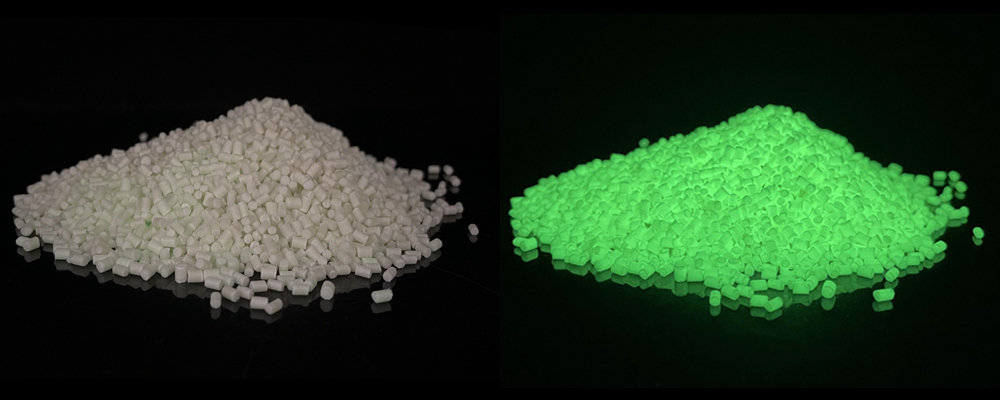

In today’s diversified market demand, luminous materials are no longer just meeting the needs of building safety, but more integrated into various industries, giving products a new visual and functional experience. As a leading supplier of glow in the dark industry, we lead this trend by providing customized modified glow in the dark masterbatch to customers, thereby creating unique products.

Amidst intensifying market competition, product differentiation is the key to success. Based on the glow-in-the-dark features of our powders and masterbatches, we are committed to meeting the diverse needs of our clients. We can incorporate the following six modified features into glow in the dark masterbatch:

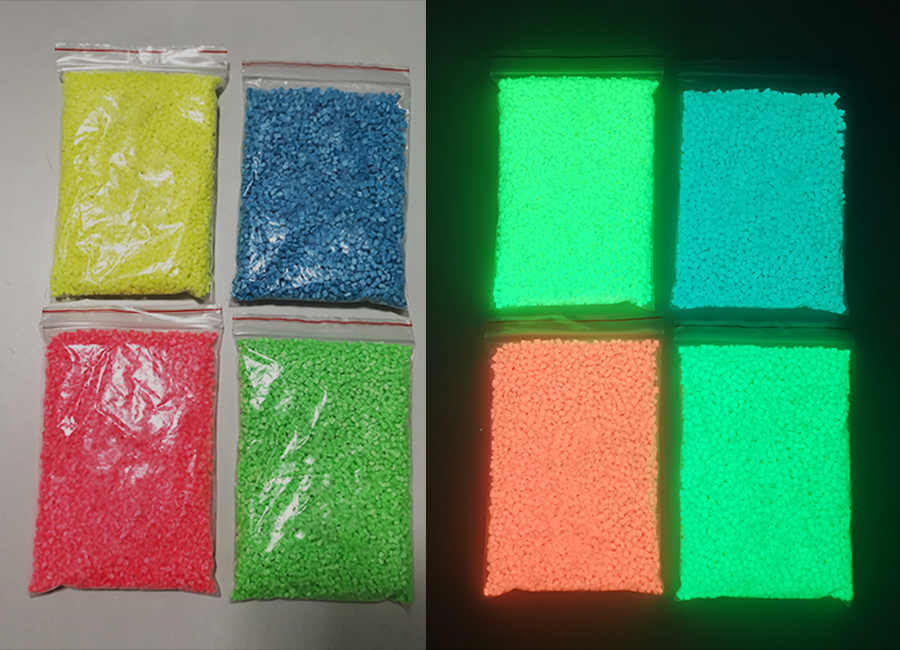

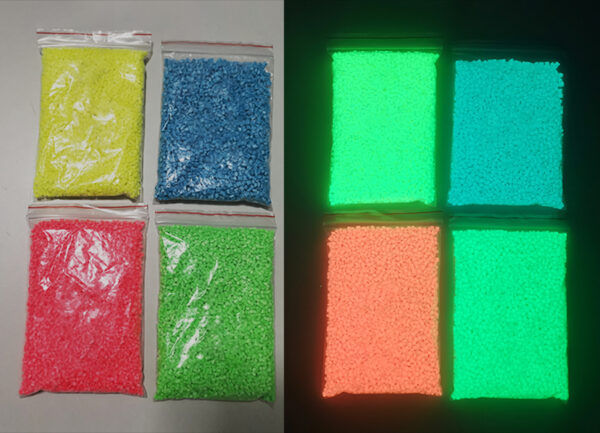

1. Custom Daytime Body Colors: Colorful World in the Night:

We can make products in various colors as per your needs. This ensures your products glow in the dark at night and stand out with specific colors during the day.

2. Conductive Ability: Leading Domestic Innovation:

Metal isn’t the only choice for conductivity and heat. Our glow-in-the-dark masterbatch can also conduct and transfer heat. They can replace metals in many areas, making products lighter and more flexible in design.

3. Wear Resistance: Dual Benefits of

Protection and Enhancement:

We lead in domestic wear-resistant technology. We can incorporate this feature into our glow-in-the-dark batchmate , it can not only reduce noise and provide lubrication but also give products a shiny surface. This decreases scratches and keeps products performing great under tough conditions.

4. Structural Enhancement: Lightweight and Strong Material Choice:

Our glow-in-the-dark masterbatch can strengthen structures by adjusting weight, adding fibers, and fillings. This reliably ensures product strength and stability. For cosmetic packaging materials,There are already mature cases of lipstick caps.

5. Flame Retardancy: Safe Protective Barrier:

Safety is a top concern. Our glow-in-the-dark masterbatch can be flame retardant, playing a vital role in fire protection in product design, ensuring safety for people and equipment. Common applications like electrical switches.

6. Thermoplastic Elastomer: Comprehensive Protection Material:

In different environments, our glow-in-the-dark masterbatch can replace traditional silicon as explosion-resistant material, providing higher protection levels for products. For instance, the glow-in-the-dark button on a flashlight.

Our mission is to create excellent and creative glow-in-the-dark solutions for customers, giving products new possibilities. We’ll keep innovating, working closely with customers in a new era of glow-in-the-dark materials. If you have any needs or ideas about customized high-performance glow-in-the-dark masterbatch, feel free to contact us. Let’s shine with creative light in the dark together!

You Might Also Like