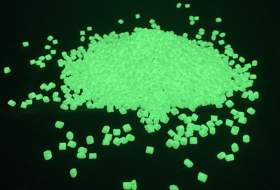

Silicone products are widely used in consumer goods due to their soft and comfortable texture, high temperature resistance, and non-toxic and eco-friendly properties; similarly, they are a common end product for glow-in-the-dark powder. Today, we focus on one such product, the glow-in-the-dark silicone watch strap.

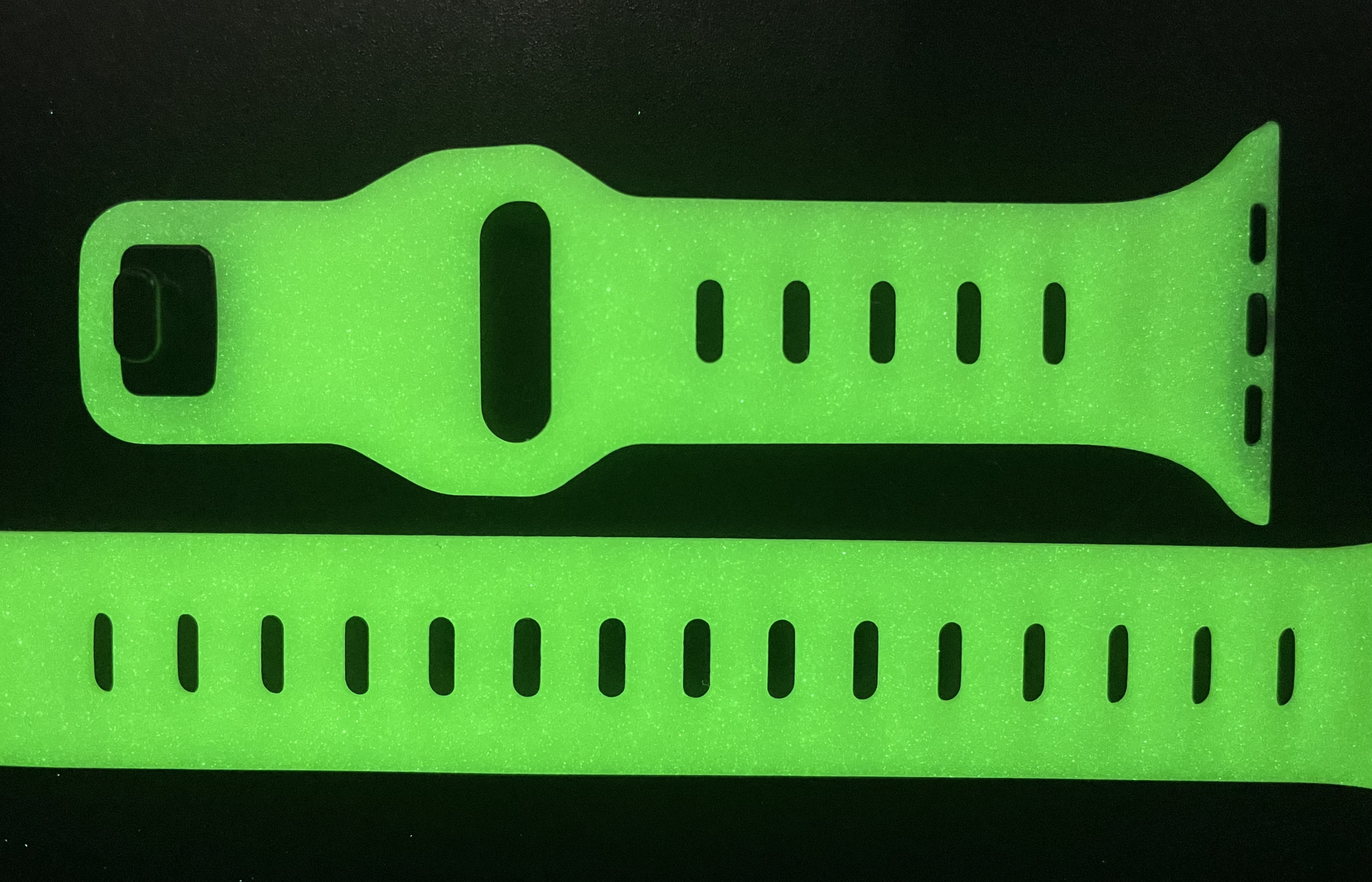

During processing in the customer’s workshop using our glow-in-the-dark powder, it was found that the silicone product displayed a speckled appearance, failing to achieve the expected transparent unity of the watch strap.

The analysis suggests that the core issue was the large particle size of the glow-in-the-dark powder used, which led to uneven mixing with the silicone material, resulting in a spotty appearance.

To resolve this issue, it’s a simple matter of adjusting the size of the particles; currently, the particles used are 250 mesh, which can be reduced to 400 mesh. Additionally, improvements can be made in the mixing process by altering the method of adding the powder to a slow, gradual addition in smaller amounts and increasing the mixing time. Another option could be to switch from using dye powders to pigment pastes to prevent the speckling.

In conclusion:

Silicone processing and product diversity mean that encountering issues during the initial trial phase of mixing glow-in-the-dark powder with silicone is fairly common. By calmly analyzing and identifying the root cause, we can effectively resolve these issues. The accumulated experience in product processing also becomes a valuable reference, helping others avoid similar difficulties.